Anarkia333data.center

La Nouvelle Alexandrie Métaphysique

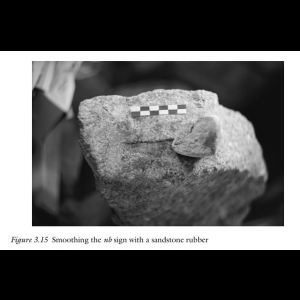

Lissage avec Grès/Cuir/Poudre

Menu - Mégalithes

- (Mégalithes et Anomalies) [12]

- (Mégalithes et Calculs) [15]

- (Mégalithes et Représentations) [10] Expand Secondary Navigation Menu

-

(Mégalithe et Techniques) [121]

Expand Secondary Navigation Menu

- Autres (Mégalithe et Techniques) [0]

- Abattage par le Feu [2]

- Abrasion - Blocs [0]

- Abrasion - Machines [4]

- Abrasion - Outils [13]

- Abrasion - Scie/Strie [1]

- Abrasion - Trou/Strie [6]

- Abrasion - Sarcophages [0]

- Abrasion - Vases [0]

- Cabestan [1]

- Carrières [1]

- Coeff. de Résistance [5]

- Coeff. de Sécurité [1]

- Corde - Câble [4]

- Dureté [6]

- Etat de Surface [0]

- Moulage [2]

- Levage [1]

- Maladie [1]

- Martelage [2]

- Masse [1]

- Mortoise [1]

- Outils [12]

- Poulie [3]

- Rondins et RDM [12]

- Tolérances générales [2]

- TOP Mégalithes [1]

- Traction - Animal [4]

- Traction - Humaine [3]

- Transport - Essaie réel [6]

- Transport - Techniques [7]

- Séisme [2]

- (Mégalithe et Métaphysique) [0]

- (Mégalithe : Théories) [8]

- (Prouesse Antique) [4]

- (Taille et Exp.) [20]

- Australie [1]

- Bolivie [2]

- Cambodge [0]

- Chine [0]

- Corse [0]

- Egypte [13]

- Espagne [0]

- Éthiopie [5]

- France [0]

- Grèce [0]

- Île de Pâques [0]

- Inde [10] Expand Secondary Navigation Menu

- Iran [1]

- Italie [2]

- Japon [0]

- Malte [0]

- Mexique [0]

- Pérou [10]

- Proche-Orient [14] Expand Secondary Navigation Menu

- Russie [0]

- Sardaigne [0]

- Turquie [0]

- Uk [4]

Copyright All Rights Reserved

Developed & Designed by Alaa Haddad